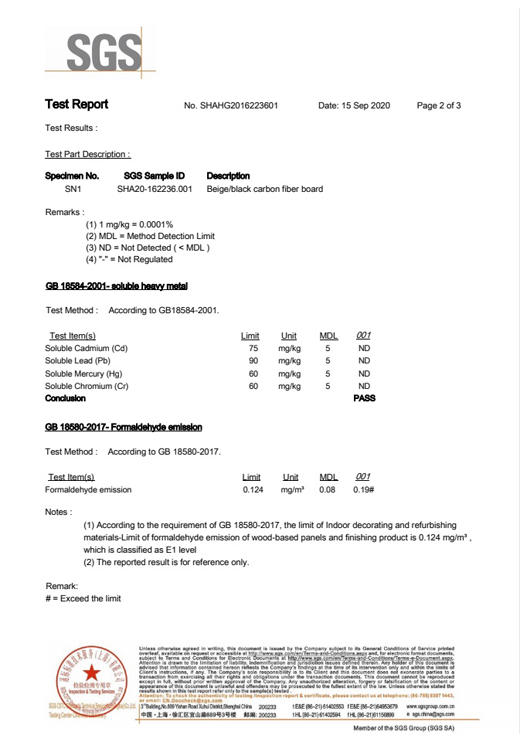

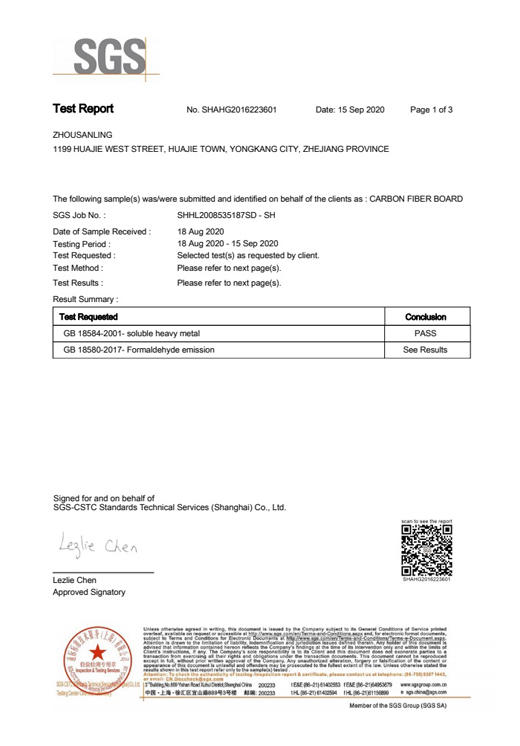

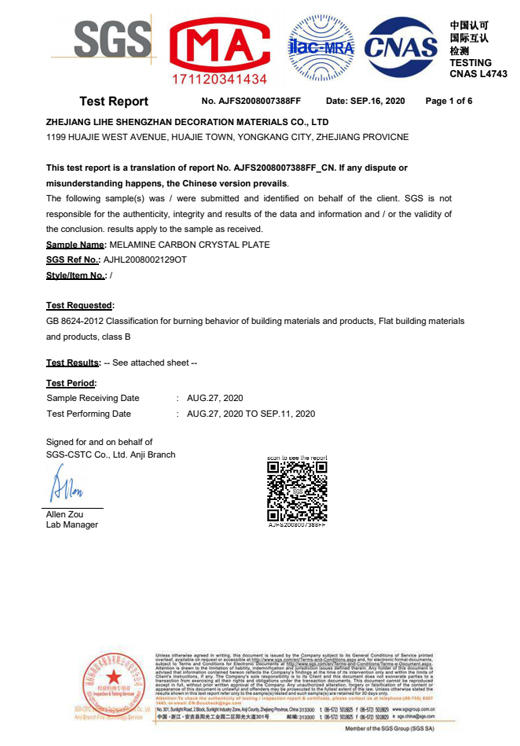

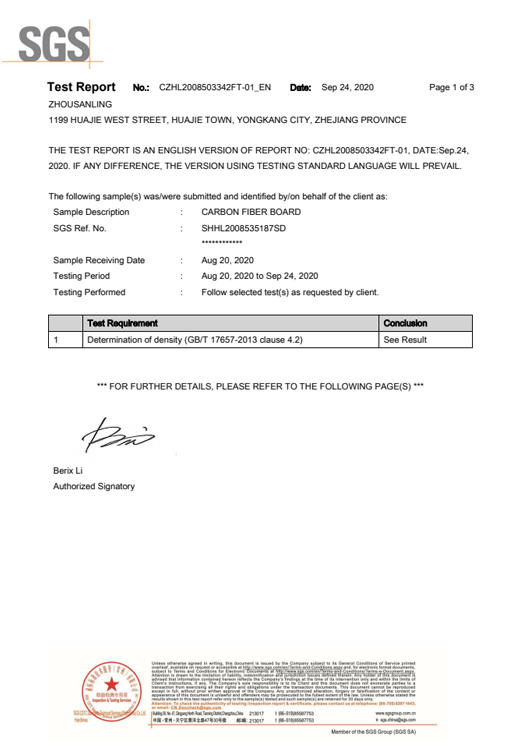

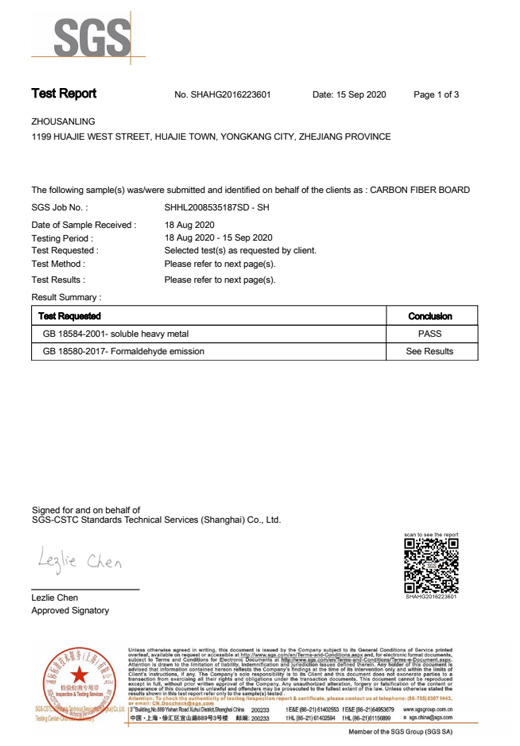

We have our quality inspection team,which can ensure the quality of the products.

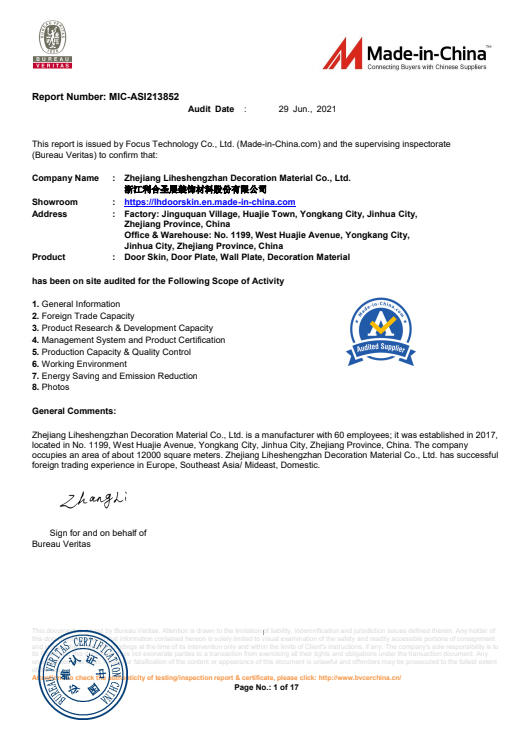

Zhejiang Lihe Shengzhan Decoration Material Co., Ltd. was established in 2014, located in Yongkang City, Zhejiang Province, the "Capital of China Hardware". As a professional China Edge Banding manufacturers and Edge Banding factory, we focus on producing various veneer panels and lines for door factories and furniture factories. The main products are melamine veneer board (paper), particle board, MDF door skin, HDF door panel, high-grade joinery, plywood, laminate, door, hardware parts, decorative board, decorative lines, etc. Our company has the right to export, and is a comprehensive factory integrating R&D, production, sales and service. The factory covers an area of about 20,000 square meters, with standardized production workshops such as blanking, cutting, washing, hot pressing and packaging, etc. The workshop has a series of advanced equipment such as cutting machines, foam machines, laser cutting machines, spray painting lines,molding machine, flat machine, engraving machine and so on. The company has passed ISO 9001 quality management system, ISO 14001 environmental management system, with a complete quality management system. Our products are exported to North America, Europe, Southeast Asia, South America, , Africa and other areas, and we also provide brand processing services for major trading companies, providing one-stop service for customers from product mould design and development, quality control and production delivery. The company's business belief is: "high quality, cheap price, high efficiency". We are willing to take the customer's requirements as our own responsibility, constantly innovate, The company's business belief is: "high quality, cheap price, high efficiency". We are willing to take the customer's requirements as our own responsibility, constantly innovate, with the products, and the perfect service to thank our customers for their support.

英语

英语 西班牙语

西班牙语 俄语

俄语 土耳其语

土耳其语 阿拉伯语

阿拉伯语